Program Codes

Before milling, writing CNC milling G and M-codes for the operation

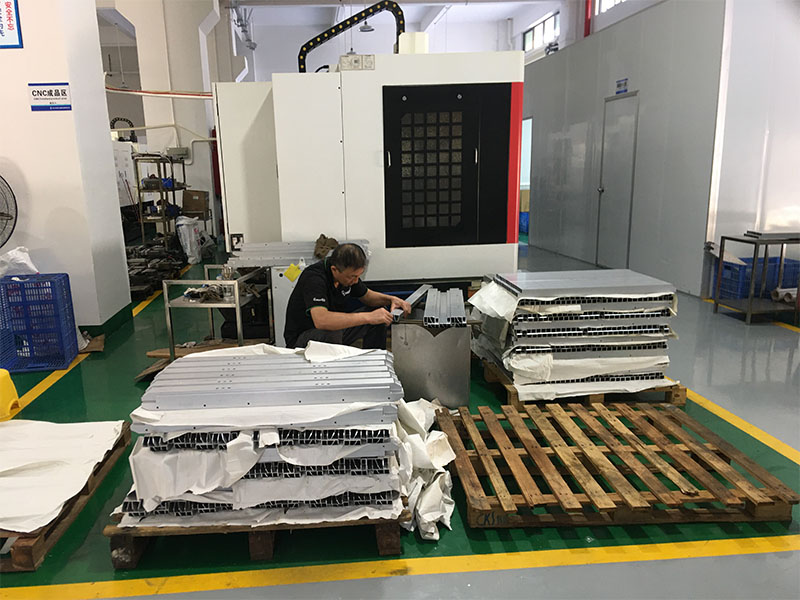

Milling Machining

Processing CNC milling parts by CNC machines, 3 axis, 4 axis, 5 axis milling

Advantages Of CNC Milling

Satisfy with complex CNC milling parts requests, higher accurate dimension

CNC Milling Application

CNC milling parts are applied in more industries, like automobile, electronic, mechanical

CNC machining is one of the revolutionary technologies that came to this earth. You know, from previous articles, we learned what CNC machining is. Well, this machining may include different types of operations. For example, turning, milling, and drilling or boring are noteworthy. Similar to other machining methods, CNC milling is prevalent in many applications. Its tight tolerance (up to 0.01mm) makes CNC milling parts reliable in many industries.

CNC milling parts may include different types of metal parts, engine components, tools & equipment, and many more. These precision milling parts are widely popular in many industries, from automotive to aerospace. Well, this article will explain all these essential pieces of information in brief. It highlights the features & benefits of CNC milling machines. It also discusses some design considerations for CNC milling parts. So, let’s explore more.

What Is CNC Milling?

From the name, we get an abbreviation, which is CNC. It means Computer Numerical Control. Well, a CNC milling machine is renowned for precision & automation. It is a technique in modern manufacturing that can create intricate metal parts with high accuracy. You may wonder about the difference between CNC milling & turning methods. The turning method typically rotates the workpiece, and a cutting blade removes the material. On the other hand, the milling method rotates the cutting tool, and the workpiece remains stationary.

Like other CNC methods, the milling machine also requires consistent G and M-codes for the operation. The code typically commands the spindle holding the cutting tool to rotate and move following the coding sequences. This way, precision CNC milling parts are created. Indeed, they come with high precision and excellent surface finish. However, you may need additional polishing & grinding. Well, it depends on your project requirements.

Types Of CNC Milling Operations

You know, CNC turning has some limitations in removing material in specific directions. Yes, CNC milling opens up multiple directions of material removal, which the turning machine couldn’t. Therefore, milling is very popular in modern manufacturing. However, we may find various milling operations based on different workpiece forms. The following four operations are the most common. Indeed, each of these methods has its own set of applications & advantages.

Face Milling:

In this milling method, the rotation axis is perpendicular to the workpiece surface surface. Various structural components, engine cylinder heads, and metal panels are some noteworthy examples.

Angular Milling:

In this milling method, the rotation axis is at a certain angle to the workpiece surface. Chamfers & bavels on the edges of CNC milling machine components are the best examples of this milling method.

Form Milling

produces non-flat cuts such as contours, curves, and radii. To generate a precise form cut, each sort of curve will necessitate the use of a unique cutting tool.

Plain Milling:

In this milling method, the rotation axis of the cutting tool is parallel to the workpiece surface. The cutting tool usually removes the material along the surface of a workpiece. You can imagine a few examples of plain milling. The flat surface on components, slots & grooves, and keyways in shafts are noteworthy examples.

Features & Benefits

So, the biggest advantage of using CNC milling machines is the ability to cut in multiple directions. Indeed, we find them the most suitable for making complex part requirements. On the other hand, these devices offer high precision and accuracy. Definitely, you can achieve the highest tolerance up to 0.01 mm.

Another remarkable benefit is the customization or prototyping ability. You know, the other customization methods, such as metal casting or molding, can be expensive and time-consuming. In this case, a CNC milling machine can save both time and cost at the same time. Therefore, these devices are extremely suitable for prototyping and customization services.

However, other benefits such as speed & efficiency, no human error, and versatility are also noteworthy. Obviously, all these benefits make CNC machining milling parts reliable in every industry.

How Does A CNC Milling Machine Work?

Like other CNC machining processes, the milling method also follows similar working steps. CNC milling also starts with machine setup and placing appropriate cutting tools. You know, we have seen various milling operations along with various types of milling machines. Therefore, the machine setup is a very important step for every milling operation.

The following steps are designing & programming, machining, and finishing. Note: You have to insert consistent coding sequences. Yes, it avoids inappropriate cutting or creating any hazardous situations. However, the finishing process may include various surface treatment procedures. Depending on various requirements, you may need additional finishing processes.

Applications Of Precision CNC Milling Parts

CNC milling is a versatile solution for most metal parts manufacturing. For this reason, most CNC milling parts manufacturers focus on high-quality milling machines. This reliability makes the CNC milling parts popular in many applications. Starting from the automotive to aerospace industries, precision milling parts are used.

| Industry – Application Place | Example Metal Parts Names |

| Automotive | Intricate engine components: turbine blades, engine housings, and structural elements |

| Medical Industry | Surgical instruments, orthopedic implants, and custom prosthetics |

| Electronic Industry | Custom connectors, PCB milling, electronic enclosures |

| Machinery | Mechanical assembly parts |

| Precision Engineering & Tool Making | Precision tools & molds used in various manufacturing processes like metal casting |

| Custom Prototyping | Prototypes for new products & designs |

| Automated Manufacturing | Conveyor systems, robotic components, and assembly line parts |

Design Considerations For CNC Milling Machine Parts

Designing is the most important step of CNC milling manufacturing steps. Well, we can design the objects on various computer software. You may be already familiar with these software. For example, AutoCAD, Solidworks, CATIA, Fusion 360, and NX are noteworthy.

You can also make a simulation program to observe the milling process. Why is it necessary? Yes, it helps reduce the machining error. In addition, it also achieves the improved design quality. However, during the design process, we all should focus on the following five factors.

1 Size & Complexities: When you decide the part size and complexity, you can decide what type of milling operation you need. Is it a face milling? Or plain milling? Or multiple-axis milling? In addition, the size & complexity determines the type of CNC milling machine.

2 Used Material: Material selection is another vital factor that we must consider. Indeed, the chosen material must meet the application’s requirements. For example, we can’t choose aluminum for high-strength applications. On the other hand, we can’t choose steel for low-weight applications.

3 Tolerances & Surface Finish: Well, this is also one of the most important factors that we must consider. Different applications may require different levels of precision or tolerances. Applications in automotive & aerospace require a smooth surface finish with the highest tolerance. On the other hand, construction applications may not require such a level of accuracy.

4 Appropriate Cutting Tools: Different components may require different cutting tools. For example, end mills, drill bits, ball cutters, face mills, and fly cutters are noteworthy cutting tools.

5 Fixtures For Clamping: Finally, to securely hold workpieces, fixtures like clamps and custom jigs are necessary. Proper clamping ensures part accuracy and efficient production.

Common Milling Defects & Why Use CNC Milling

Why use CNC milling? Yes, it ensures the highest quality of the machined parts. You may know some traditional machining processes like manual lathe or metal casting. You may often find some milling defects in these traditional methods. For example, dents, irregular surface finish, burns on the surface, and burrs are some common examples.

Here comes the reason for using the CNC milling technique. You know, a CNC machine barely makes mistakes unless you insert the wrong information into the device. A man can make mistake but a machine can not! So, simply, we can rely on CNC milling techniques. However, we may also consider other benefits as well. Overall, it proves that CNC milling is better than any traditional milling method that came to this earth.

Precision And Accurate Dimensions

CNC Milling VS CNC Turning

Both CNC milling & CNC turning are popular in many industries requiring metal parts. In addition, both of them are famous for producing high-precision metal parts. Yes, you can achieve tolerances up to 0.01mm. These two CNC machining uses G-code & M-code to control the spindles. However, there are some differences between them. Let’s explore more in the following table.

| Aspects | CNC Milling | CNC Turning |

| Method Of Cutting | The method keeps the workpiece stationary. A rotating cutting tool removes the material from this workpiece | This method keeps the cutting tool stationary. It moves along the rotating workpiece to make various shapes |

| Workpiece Shape | This method is suitable for producing parts with flat or complex surfaces. You can also work with 3D geometries | This method uses cylindrical or conical shapes of workpieces such as shafts, screws, and bushings |

| Tool Movement | The tool can move along X, Y, and Z axes. You may often find 4-axis or 5-axis milling | The tool only moves along the Z-axis |

| Types Of Cutting Tools | End mills, drill bits, ball cutters, face mills, and fly cutters | Inserts, turning tools, boring bars, and threading tools |

| Types Of Machined Parts | Complex parts, molds, prototypes, and components with intricate shapes | Shafts, screws, bushings, and cylindrical components |

| Applications | All industries | All industries |

Frequently Asked Questions

What Are CNC Milled Parts?

Simply, the parts made from a CNC milling machine are called CNC milled parts. Indeed, CNC milled parts come with high precision and accuracy. Although, based on various application requirements, you can customize this accuracy. However, CNC milled parts are extremely popular in different industries worldwide.

Can Carbon Fiber Be CNC Milled?

Yes, carbon fiber can be CNC milled. But it requires specialized tools & techniques due to its abrasive nature. In addition, the process allows for precise shaping & cutting of carbon fiber composites.

Can A CNC Mill Cut Steel?

Yes, a CNC mill can cut different types of steel. With the appropriate tooling parameters, you can efficiently machine various types of steel. As a result, CNC machines are called versatile solutions for all industries.

Let’s discuss your project